Business Process Optimization Strategies That Increase Efficiency

Summary

ToggleRunning a business often feels like juggling flaming torches while riding a unicycle. Between managing teams, serving customers, and keeping the lights on, it’s easy to get caught in the daily grind without stepping back to ask: “Are we optimizing business processes in the most efficient way?”

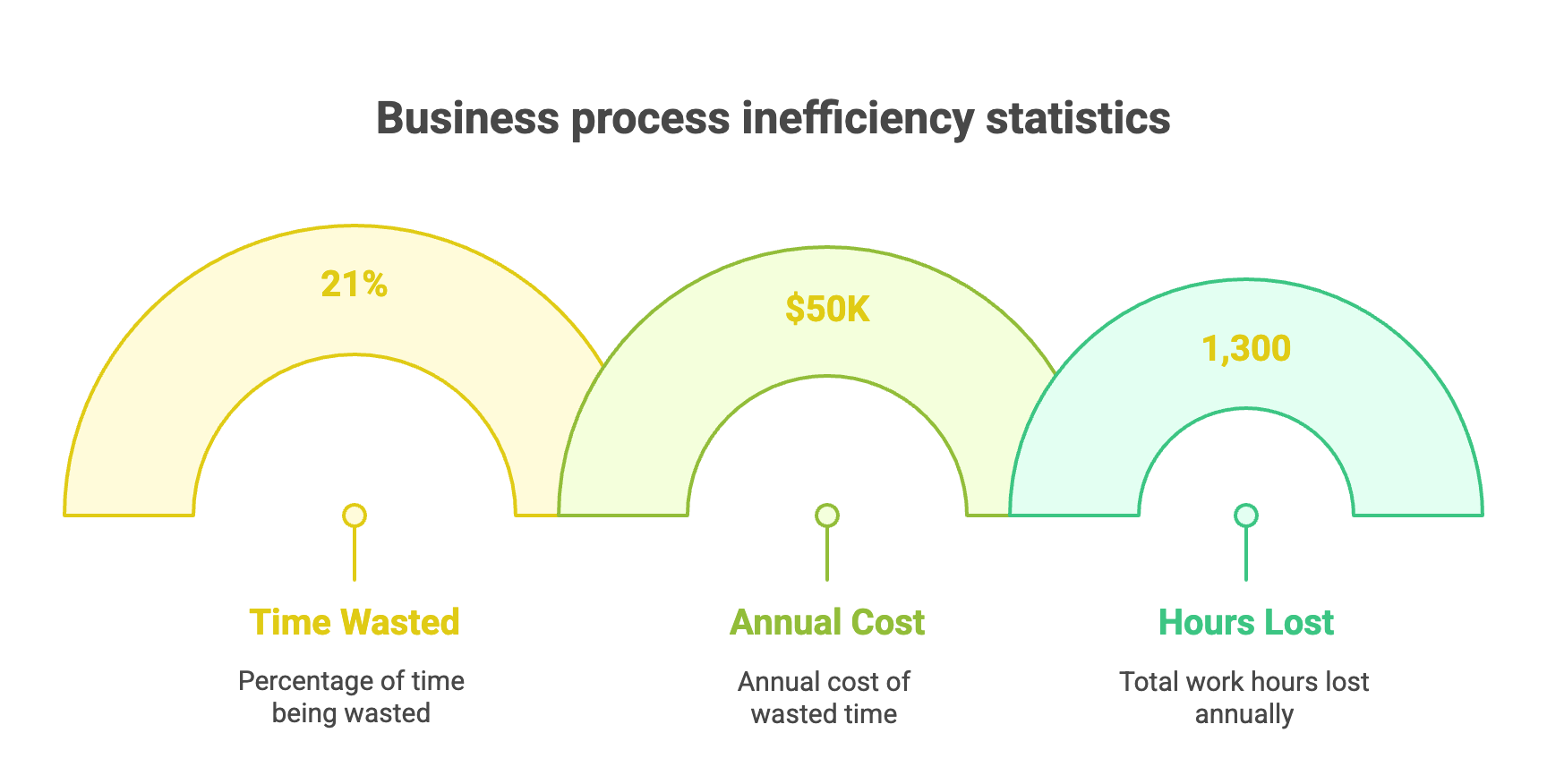

If you’re a business owner, founder, or operations manager feeling overwhelmed by inefficient processes, you’re not alone. Recent studies show that businesses waste up to 21% of their time on process inefficiencies in poorly designed processes. But here’s the good news: the companies that invest in process optimization see an average efficiency increase of 40%.

Ready to transform your operations with business process improvement? Discover how Olqan streamlines business processes with our all-in-one platform designed for growing businesses.

In this article, we’ll dive deep into 10 proven strategies that successful businesses use to streamline their operations, eliminate waste, and create systems that actually work.

Why Process Optimization Matters More Than Ever

Before we jump into the strategies, let’s address the elephant in the room: why should you care about process optimization when you have a business to run?

The answer is simple. Inefficient processes are profit killers.

Consider this: if your team spends just 30 minutes daily on unnecessary tasks, that’s 2.5 hours per week, 130 hours per year, per employee. For a team of 10, that’s 1,300 hours of wasted productivity annually—equivalent to hiring an additional part-time employee, highlighting the need for business process optimization.

But process optimization isn’t just about saving time. It’s about:

- Reducing errors that cost money and damage reputation

- Improving employee satisfaction by eliminating frustrating roadblocks

- Scaling efficiently is key to achieving your business goals. without proportionally increasing overhead

- Creating predictable outcomes that support better decision-making

Strategy 1: Map Your Business Current Processes (The Foundation)

You can’t optimize what you don’t understand. The first step is creating a clear picture of how work actually flows through your organization.

How to Do It:

- Choose one critical process to start (don’t try to map everything at once)

- Follow the work to optimize the process and improve outcomes., not the org chart

- Document every step, including handoffs, approvals, and delays

- Note pain points where work gets stuck or duplicated

Real Example:

A marketing agency discovered their client onboarding process had 23 steps spread across 4 different tools. By mapping it out, they identified 8 redundant steps and reduced onboarding time from 2 weeks to 3 days.

Tools That Help:

- Process mapping software (Lucidchart, Miro)

- Simple flowchart tools

- Even pen and paper works for small processes

Olqan Advantage: While external tools work, Olqan’s features integrate directly with your actual workflows, making optimization seamless and actionable.

Strategy 2: Eliminate Handoff Delays

Every time work passes from one person to another, there’s potential for delay, miscommunication, and errors. The goal isn’t to eliminate all handoffs (that’s impossible), but to make them seamless through effective process optimization.

How to Reduce Handoff Friction:

- Standardize information transfer with templates and checklists

- Set clear expectations for response times

- Use centralized tools instead of email chains

- Create accountability with tracking and notifications

Case Study:

A software company reduced their bug fix cycle from 5 days to 2 days by implementing a standardized handoff process between QA and development teams. They created templates for bug reports and set up automated notifications for status updates.

📋 Related Resource: See how Olqan’s team collaboration features eliminate communication bottlenecks with centralized messaging, automated notifications, and seamless project handoffs.

Strategy 3: Automate Repetitive Tasks And Optimize Your Business

If your team is manually doing the same task more than once a week, it’s probably a candidate for automation. But here’s the key: automate the right things to improve processes effectively.

Best Automation Candidates:

- Data entry Integration between systems is vital for streamlining processes across departments.

- Status updates and notifications

- Report generation and distribution of the product or service is crucial for success.

- Routine communications (follow-ups, confirmations)

- File organization and backup

Overall Process Automation That Actually Works:

Start small. Instead of trying to automate entire processes, focus on individual tasks that:

- Take more than 5 minutes to complete manually

- Happen frequently (daily or weekly)

- Follow the same steps every time

- Don’t require complex decision-making

ROI Calculation:

Before automating anything, calculate the return on investment:

- Time saved per task × Frequency × Hourly cost = Monthly savings

- Compare this to the cost of automation tools and setup time

💡Olqan Tip: Our platform includes built-in finance console that can handle data entry, status updates, and routine communications without requiring technical expertise or additional software costs.

Strategy 4: Standardize Communication Protocols

Poor communication is the silent killer of business efficiency. Teams waste countless hours clarifying unclear instructions, searching for information, and dealing with miscommunications.

Create Communication Standards For:

- Meeting agendas and outcomes

- Project status updates

- Client communications

- Internal requests and approvals

- Emergency procedures

The SBAR Framework:

Use this simple structure for important communications:

- Situation: What’s happening?

- Background: What’s the context?

- Assessment: What do you think the issue is?

- Recommendation: What should we do?

Strategy 5: Implement the “Two-Touch Rule”

Every piece of information, document, or task should be touched a maximum of two times: once to review/process it, and once to complete or forward it within the optimization process.

How to Apply the Two-Touch Rule:

- When you open an email, either respond immediately (if it takes less than 2 minutes), schedule time to handle it, or delegate it

- When reviewing documents, it’s important to optimize the process to ensure accuracy., make decisions on the spot rather than repeatedly reviewing the process to ensure efficiency.

- For tasks, either do them immediately or schedule specific time to complete them

This simple rule eliminates the productivity drain of constantly re-reviewing the same items.

Strategy 6: Create Decision Trees for Common Scenarios

Many businesses slow down because team members don’t know who makes which decisions or what criteria to use. Decision trees solve this by providing clear frameworks.

Common Areas for Decision Trees:

- Customer service escalations

- Pricing negotiations

- Effective resource allocation is essential for optimizing business processes.

- Quality control issues

- Vendor selection

Example Decision Tree:

Customer Complaint Received

↓

Is it a billing issue within the existing process?

├─ Yes → Forward to Accounting Team

└─ No → Is purchase > $500?

├─ Yes → Manager approval required

└─ No → Customer service resolves directly

Strategy 7: Batch Similar Tasks

Context switching kills productivity. Every time you switch between different types of tasks, your brain needs time to refocus. Batching eliminates this waste.

Effective Batching Strategies:

- Email processing: Check and respond to emails at set times (e.g., 9 AM, 1 PM, 4 PM)

- Administrative tasks: Handle all admin work in dedicated blocks

- Client calls: Schedule similar meetings back-to-back

- Content creation: Write multiple pieces in focused sessions

The Results:

Companies that implement task batching report 25-40% improvements in focused work time and significantly reduced mental fatigue.

Strategy 8: Use the 80/20 Rule for Process Improvement

Not all processes are created equal; some require optimization projects to enhance efficiency. The Pareto Principle suggests that 80% of your results come from 20% of your efforts. The same applies to process optimization.

How to Identify High-Impact Processes:

- List all your business processes

- Rank them by impact on customer satisfaction, revenue, or operational efficiency

- Focus optimization efforts on the top 20%

- Measure improvements in the new process. before moving to the next process

Focus Areas That Deliver Maximum Impact:

- Customer onboarding

- Sales pipeline management

- Product/service delivery

- Invoice and payment processing

- Customer support resolution

Strategy 9: Implement Continuous Feedback Loops

Optimization isn’t a one-time project—it’s an ongoing practice. Build feedback mechanisms that help you continuously identify and fix inefficiencies.

Feedback Mechanisms That Work:

- Weekly team retrospectives: What worked? What didn’t? What should we change?

- Customer feedback surveys: Where do clients experience friction?

- Process metrics tracking: Monitor key performance indicators

- Employee suggestion systems: Front-line workers often see problems leadership misses

Key Metrics to Track:

- Cycle time in business process management is crucial for improving efficiency.: How long does it take to complete a process?

- Error rates: How often do mistakes happen within the production process?

- Handoff delays can significantly impact the optimization process.: Where does work get stuck?

- Resource utilization: Are people and tools being used efficiently?

📊 Measurement Made Easy: Track your optimization progress with business process management tools to ensure effective process optimization involves all team members. Olqan’s performance dashboards help identify process bottlenecks. that provide real-time insights into process efficiency, cycle times, and team productivity.

Strategy 10: Design Processes for Scale

The processes that work for a 5-person team might collapse at 50 people. Design your systems with growth in mind.

Scalable Process Characteristics:

- Clear documentation that new employees can follow

- Defined roles and responsibilities that don’t depend on specific individuals

- Measurable outcomes that maintain quality as volume increases

- Flexible frameworks can help implement business strategies effectively. that adapt to changing business needs

Questions to Ask:

- Will this process work if we double our team size?

- Can new employees follow this without extensive training?

- Does this process depend on any single person’s knowledge?

- Can we measure success consistently in our process optimization initiatives?

Putting It All Together: Your 90-Day Implementation Plan

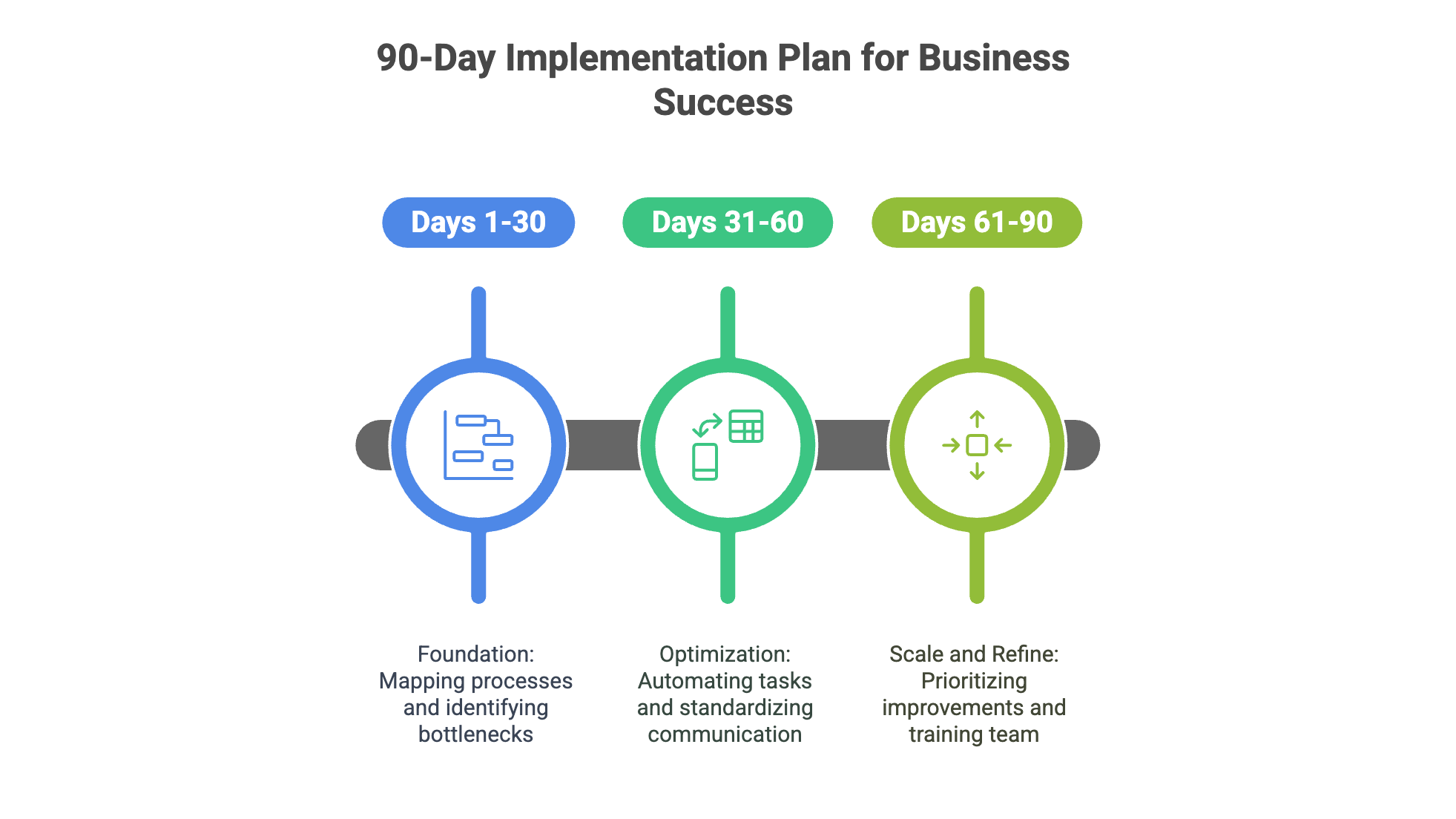

Implementing all these strategies at once is a recipe for overwhelm. Here’s a phased approach that actually works:

Phase 1 (Days 1-30): Foundation

- Map 2-3 critical processes

- Identify the biggest bottlenecks

- Implement the two-touch rule

- Start batching similar tasks

Phase 2 (Days 31-60): Optimization

- Automate 2-3 repetitive tasks

- Create decision trees for common scenarios

- Standardize communication protocols

- Set up basic feedback mechanisms

Phase 3 (Days 61-90): Scale and Refine

- Apply the 80/20 rule to prioritize further improvements

- Document optimized processes for scalability

- Train team members on new procedures

- Measure and celebrate improvements

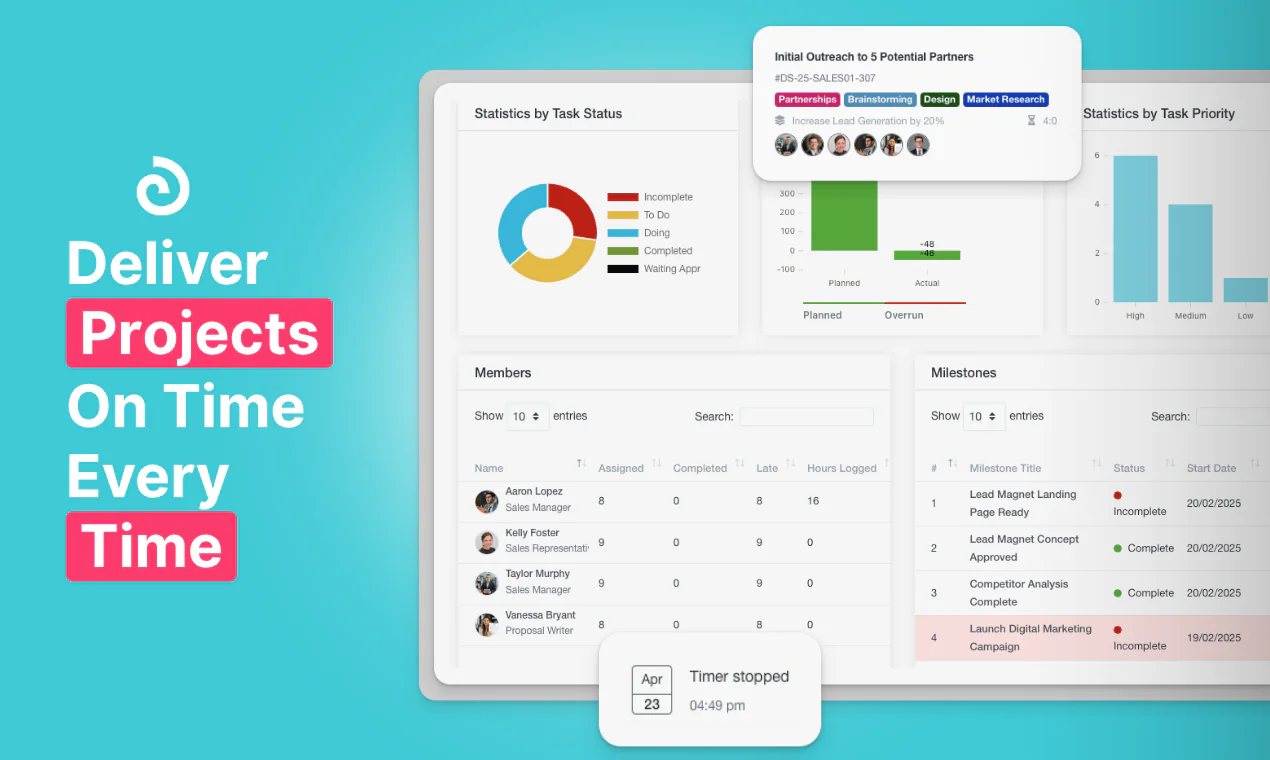

The Role of Technology in Process Optimization

While you can optimize processes manually, the right technology platform can accelerate your results significantly. An all-in-one business platform like Olqan’s Work Management Suite Process optimization requires a commitment to continuous improvement.

- Centralize all your processes in one system instead of juggling multiple tools

- Automate handoffs between different business functions

- Track performance with built-in analytics and reporting

- Scale efficiently as your business grows

The key is choosing technology that supports your optimized processes rather than forcing you to adapt to the tool’s limitations.

🚀 See It In Action: Schedule a demo to see how Olqan transforms business operations with integrated process management, automation, and analytics.

Common Pitfalls to Avoid

As you implement these strategies, watch out for these common mistakes:

1. Optimizing the Wrong Things

Don’t optimize processes that shouldn’t exist in the first place; focus on improving existing processes instead. Sometimes the best optimization is elimination.

2. Over-Engineering Solutions

Simple solutions often work better than complex ones. Start with the simplest approach that solves the problem.

3. Ignoring Change Management

Process changes affect people. Communicate the benefits, provide training, and get buy-in from your team.

4. Perfectionism Paralysis

Don’t wait for the perfect solution. Implement good-enough improvements and iterate based on feedback to drive business process improvement.

Measuring Your Success

How do you know if your optimization efforts in the existing process are working? Track these key indicators:

Efficiency Metrics:

- Time to complete key processes

- Number of handoffs required

- Error rates and rework instances

- Employee productivity measures

Business Impact Metrics:

- Customer satisfaction scores

- Revenue per employee

- Time to market for new products/services

- Operational cost as percentage of revenue

Team Satisfaction Metrics:

- Employee engagement scores can be improved by implementing new processes.

- Time spent on frustrating tasks

- Clarity of roles and responsibilities

- Confidence in decision-making

Your Next Steps

Process optimization isn’t about perfection—it’s about progress in your optimization projects. Even small improvements in business process automation compound over time to create significant competitive advantages.

Start today with these actions:

- Choose one process that frustrates your team daily

- Map out the current state in 30 minutes or less

- Identify the biggest bottleneck and brainstorm solutions

- Implement one small improvement this week

- Measure the results after two weeks

Remember, the goal isn’t to optimize everything at once. It’s to build a culture of continuous improvement where efficiency becomes a competitive advantage.

Ready to transform your business operations? The strategies in this article have helped hundreds of businesses increase efficiency by 40% or more. The question isn’t whether process optimization works—it’s whether you’re ready to commit to the journey.

🎯 Ready to see these strategies in action? Discover how Olqan transforms business operations Our integrated platform combines process management, automation, team collaboration, and analytics to improve processes in one powerful solution.

Schedule a Free Demo | Join Olqan

FAQS:

Q: What is business process optimization?

A: Business process optimization refers to the practice of improving and enhancing business processes to increase efficiency, reduce costs, and improve the overall business environment. It involves analyzing existing processes, identifying areas for improvement, and implementing changes to optimize those processes.

Q: How can I implement business process optimization in my organization?

A: To implement business process optimization, start by mapping out your current business processes using a process map. Identify bottlenecks, inefficiencies, and areas for improvement. Engage process owners and stakeholders to gather input, and then prioritize optimization projects based on potential business value.

Q: What are some common process optimization examples?

A: Common process optimization examples include automating repetitive tasks using business process automation software, streamlining workflows to reduce process completion times, and utilizing process mining techniques to uncover hidden inefficiencies. These strategies can help drive business efficiency and effectiveness.

Q: What is the role of a process owner in business process optimization?

A: A process owner is responsible for managing a specific business process, ensuring its effectiveness, and driving improvements. In the context of business process optimization, the process owner plays a crucial role in identifying process issues, implementing changes, and measuring the success of optimization efforts.

Q: How can I optimize business processes to enhance business value?

A: To optimize business processes for greater value, focus on eliminating process defects and inefficiencies. Use process documentation to establish clear guidelines and standards. Regularly review and adjust processes based on feedback and performance metrics to ensure continuous improvement.

Q: What does process optimization refer to in a manufacturing context?

A: In manufacturing, process optimization refers to the strategies and techniques used to improve production processes, reduce waste, and increase output. This can involve implementing lean manufacturing principles, using process optimization software, and analyzing workflows to enhance process execution success.

Q: What are the benefits of business process mapping in optimization projects?

A: Business process mapping helps visualize and document the current state of business processes, making it easier to identify inefficiencies and areas for improvement. This clear representation aids in communication among stakeholders and serves as a foundation for developing strategies to optimize processes effectively.

Q: How does process optimization impact business workflows?

A: Process optimization positively impacts business workflows by streamlining tasks, reducing redundancies, and improving collaboration among teams. By optimizing workflows, organizations can achieve faster response times, lower operational costs, and enhanced overall productivity.

Q: What tips can help drive successful business process improvement?

A: To drive successful business process improvement, prioritize stakeholder involvement, set clear goals, and utilize data analytics to inform decisions. Additionally, ensure ongoing training for employees on optimized processes and regularly review performance to make necessary adjustments.